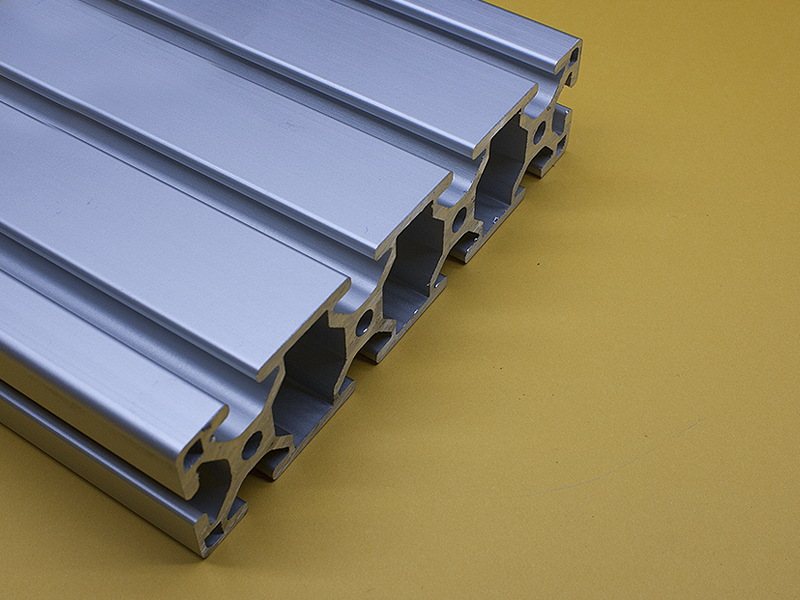

Trailer aluminum extrusions are a powerful tool for enhancing the structural integrity and durability of a trailer. Not only do they offer superior strength, but also provide additional protection against wear and tear.

Aluminum extrusion technology allows for precise customization to fit any design need, making them the perfect choice for trailers that require added stability or longevity. With increased tensile strength and corrosion resistance, trailer aluminum extrusions can help maximize performance while providing greater peace of mind on the road.

Increasing Rigidity and Strength

Increasing rigidity and strength is an important factor to consider when looking at trailer aluminum extrusions. Aluminum extrusions are a great way to create trailers that have increased structural integrity and durability, as the extruded metal creates a strong framework for any load-bearing structure.

This added layer of stability also makes it easier to attach components like side panels or roofing materials, which further enhances the overall strength of the trailer. Moreover, due to its lightweight nature, aluminum extrusions can help prevent sagging over time – something especially important in trailers with heavier payloads or long distances covered.

Furthermore, since aluminum extrusions offer greater flexibility than traditional steel frames they can be used to build more creative designs without compromising on safety or functionality. All in all, if youre looking for ways to increase rigidity and strength while creating a trailer that will last longer and perform better under stress—aluminum extrusions are worth considering!

Enhancing Corrosion Resistance

Aluminum extrusions offer an impressive level of corrosion resistance, allowing trailers to remain structurally sound and durable for many years. Extruded aluminum is a versatile material that can be treated with special coatings or finishes to further enhance its natural properties.

This includes galvanizing, which provides superior protection against rust and the elements by creating a thin layer of zinc oxide over the surface of the metal. Anodized finishes are also popular for their excellent durability and long-term performance in corrosive environments.

In addition, as extrusion technology has advanced over time so have methods of protecting metals from corrosion which has made trailer aluminum even more reliable when it comes to maintaining structural integrity and durability in harsh conditions. By utilizing these innovative techniques, businesses can ensure their trailers withstand the test of time while providing maximum return on investment over extended periods of use.

Reducing Weight Without Sacrificing Durability

Aluminum extrusions are increasingly being used in trailer construction due to their ability to provide rigidity and durability. But when it comes to reducing weight without sacrificing structural integrity, aluminum is the metal of choice.

Its light yet strong nature allows for great weight reduction while still providing a durable and lasting structure. Additionally, its malleability makes it easy to fabricate into complex shapes that can further reduce overall weight without compromising strength or longevity.

By using aluminum extrusions in trailers, manufacturers can benefit from greater payload capacities as well as increased fuel efficiency due to reduced drag and friction on the roadways. With an emphasis on both economy and performance, trailer aluminum extrusion enables users to rest assured knowing they have a structurally sound product that will last for years with minimal maintenance required throughout its lifetime.

Improving Flexibility in Design

Aluminum extrusions can be an ideal solution for improving flexibility in design. Today, aluminum alloys are capable of providing strength and durability without sacrificing the ability to customize or adjust designs quickly and easily.

With aluminum extrusion, you have the versatility to craft a design that meets your exact specifications. By using aluminum extrusions with intricate shapes and sizes, designers can create innovative solutions that improve structural integrity while maintaining a lightweight structure that\’s easy to modify. Aluminum extrusions also bring long-term benefits due to their superior durability and resistance to corrosion.

The use of these materials ensures that trailer frames remain structurally sound even after years of exposure to harsh weather conditions like rain, snow, extreme temperatures, or saltwater air. This allows for prolonged use at minimal maintenance requirements compared with other materials such as steel or wood frame structures which require frequent repair work as they are subject to more wear and tear over time.

In addition, trailers constructed from aluminum extrusions provide greater safety due to their non-flammable properties – making it ideal for use in applications where fire safety is paramount such as recreational vehicles used near campfires or flammable liquids being transported on open roadsides. Finally, aluminum alloys come in different grades of strength so they can be tailored precisely according to any application’s specific needs – this level of customization further enhances flexibility when designing trailers for varying purposes ensuring maximum performance while still looking aesthetically pleasing too!

Seamless Assembly for Long-Term Performance

The assembly of aluminum extrusions is a key factor in the structural integrity and durability of any trailer. Utilizing state-of-the-art technologies, extruded aluminum can be formed into nearly any shape desired, allowing for seamless integration with other components and providing a superior strength-to-weight ratio.

With intricate designs that are impossible to replicate with traditional manufacturing processes, trailers built using extruded aluminum are more durable than ever before. Additionally, due to their modular design and lack of welds or joints, these trailers require minimal maintenance over time while still offering optimal performance.

As a result, precision-engineered trailer aluminum extrusions provide an unparalleled level of structural integrity and long-term performance through seamless assembly.

Conclusion

Aluminum extrusion is a popular choice for aluminum extrusion manufacturer due to its structural integrity and durability. Aluminum extrusion provides a lightweight yet strong solution that can be used in various applications, such as walls, roofing, and flooring.

It also helps reduce the overall weight of the trailer which helps improve fuel efficiency. By choosing aluminum extrusions, trailer manufacturers can provide their customers with high-quality products that will last longer and perform better.

For all your aluminum extrusion needs, consider contacting an experienced manufacturer like ABC Extrusion Company which has years of experience providing quality aluminum extrusions for trailers around the world.